10 Tips to Solve Edges Warping Problem in 3D Printing

Posted by menglisa on

A common problem in 3D printing when using FDM (Fused Deposition Modeling ) is edge warping.

Fused Deposition Modeling technology FDM printer uses high temperature melting PLA/ABS and other environmentally friendly plastics to pile up layer by layer. In the process of melting and cooling, there will be the problem of warping the edges of the printed object. warping edges is one of the most headache problem in 3D printing.

When the edge warping is severe, the whole product will likely be scrapped. It is hard to repair it after the edge warping. How to prevent the edge warping phenomenon in the beginning? In this article, we will discuss different solutions to help us increase the success rate in 3D printing.

First of all, find out why the edge warping phenomenon arises.

We all know that “Thermal expansion and cold shrinkage”, which leads to the appearance of warping edges-consumables extruded from the nozzle contract during cooling. When the working area is small, the impact of shrinkage is not obvious; but when printing bigger size models/products, the cumulative contraction force per unit area becomes quite large, resulting in corners tilting up and away from the platform. In particular, ABS has a higher cooling shrinkage and is easier to warp than PLA. You should pay more attention to the edge warping problem when you are using ABS to print models.

How to avoid edge warping? Here are our suggested solutions that we can use.

1. improve the model design.

Through the design of adding edge or base, increasing the contact area between the bottom/first layer of the model and the platform can effectively reduce the occurrence of edge warping.

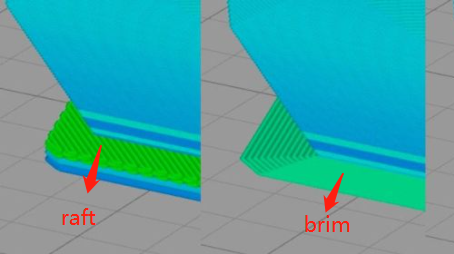

2. add raft or brim when slicing the model

When setting the model, you can add raft or brim or set the appropriate edge expansion.

3. use professional glue when you are printing with PLA filament (usually, we use PVP glue in 3D printing).

The use of special anti-warping glue can effectively prevent edge warping. PVP glue can be applied evenly on the printing platform to increase the adhesion between the model and the platform. After the 3D printing work is completed, you need to clean this PVP glue from the surface of the printing bed.

4. Use a hotbed when printing.

3D printer hotbed is a unique accessory of FDM printer. The main purpose is to prevent edge warping. By heating the hotbed, the temperature at the model’s bottom is always in a constant status. A consistent temperature at the bottom layers can effectively help to prevent the edge warping phenomenon caused by uneven heat dissipation.

5. Adjust bed leveling (leveling).

If the leveling is not good, the distance between the printing platform and the printing nozzle is too large, and the printed layer cannot be firmly glued to the printing platform. For the FDM printer, the printing quality of the first layer is particularly critical. If the distance is too small, it will prevent the nozzle from flowing out of the printing material. Too big or too small will lead to a poor foundation of the first layer. And try to make sure that the nozzle and the four corners of the platform are the proper distance.

Suppose the first layer does not adhere to the printing platform. In that case, the probability of subsequent edge warping or failure is particularly high, so the printer must be appropriately leveled according to the instructions provided by various manufacturers.

6. clean the surface of the platform before printing

Sometimes, the hands’ sweat, oil, and fingerprints will be attached to the platform, which is not easy to see with the naked eye. We can wipe clean these oils, fingerprints with a small amount of detergent before start 3D printing. Please ensure that the platform is clean and smooth.

7. Ensure a constant temperature of the working environment during printing process.

In the printing process, the ambient temperature is as constant as possible, do not put the printer in a ventilated place. It is best to choose a 3D printer with enclosure, especially when you print with ABS filament.

8. Set moderate printing speed

If you detect a warping trend in the printing process, you can slow down the printing speed appropriately, which will be alleviated a little. In particular, the speed of the first layer printing can be a little slower, to lay a good foundation.

9. Use the fans skillfully

The fan will help to accelerate the cooling of the printed layers. When printing a small product, the nozzle/print head may start printing the next layer before the model can cool down. Failure to cool down the printed layer in time will lead to the collapse of the printed model. In this case, we need a fan to speed up the cooling of the print model. But when printing a large area of work, the cooling effect of the air will accelerate the shrinkage of the plastic, but it is easy to warp the edge. For large models, the printing time of the single layer is longer, there is enough time for the printed new payer to cool down, and the model quality will not be affected if the fan is not turned on.

10. Increase the value of the first layer thickness and layer extrusion (first layer height extrusion).

If you increase the value of the first layer height, when you print the first layer of the 3D model, more glue will be squeezed onto the printing platform, thus improving the adhesion.

About first layer height: It is suggested that it is higher than 0.1mm to increase the extrusion volume and adhesion of the first layer.

About first layer extrusion: If you find a warped edge, you can increase the original 100% to 110% or 120%, or even higher, but it will have an effect similar to that of an elephant leg, set it as appropriate.

I hope the above 10 methods can effectively help you solve the problem of edges warping on your 3D printing model.

← Older Post Newer Post →

0 comments